Australia: The Main Line computer vision system will be tested on the heavy-haul long distance locomotives of the Rio Tinto mining company in the Pilbara region over the next three months. It is being implemented as part of the AutoHaul automation project by Hitachi Rail STS that has been running at Rio Tinto for several years. At the moment, it is the most automated railway system in the world and the closest one to the highest unmanned GoA4 level.

A contract for the development and testing of the obstacle detection system was signed between the Israeli company Rail Vision and Hitachi Rail STS, which is a system integrator for the AutoHaul project implemented on the Rio Tinto network in 2019. The agreement provides the possibility to extend the trials for another six months.

In fact, the new project means upgrading of the AutoHaul system and equipping it with a more advanced computer vision system. As part of the trials, it is supposed to check the ability to recognize several types of obstacles on the railway tracks or next to them at different distances from the locomotive. The contract worth up to $398k USD for creation, testing, feasibility study and implementation of a new computer vision system was concluded in May last year. Then it was stated that its integration is scheduled for the third quarter of 2021.

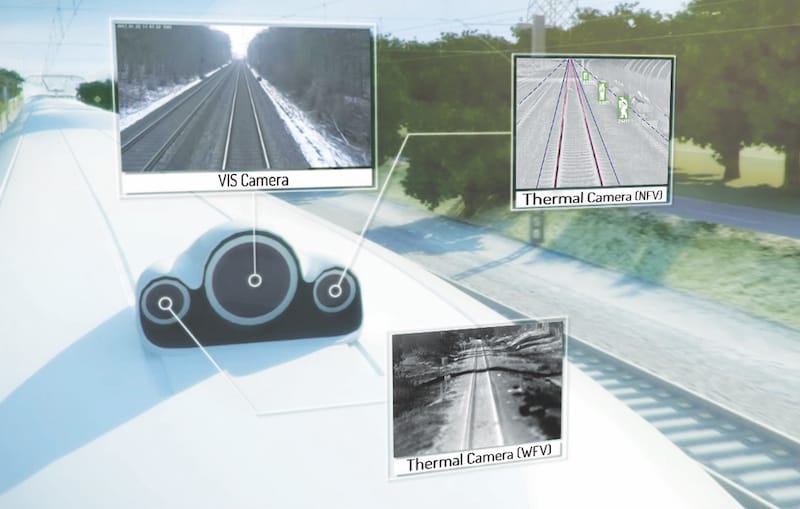

Screenshots from the Main Line System cameras. Source: Rail Vision

Screenshots from the Main Line System cameras. Source: Rail Vision

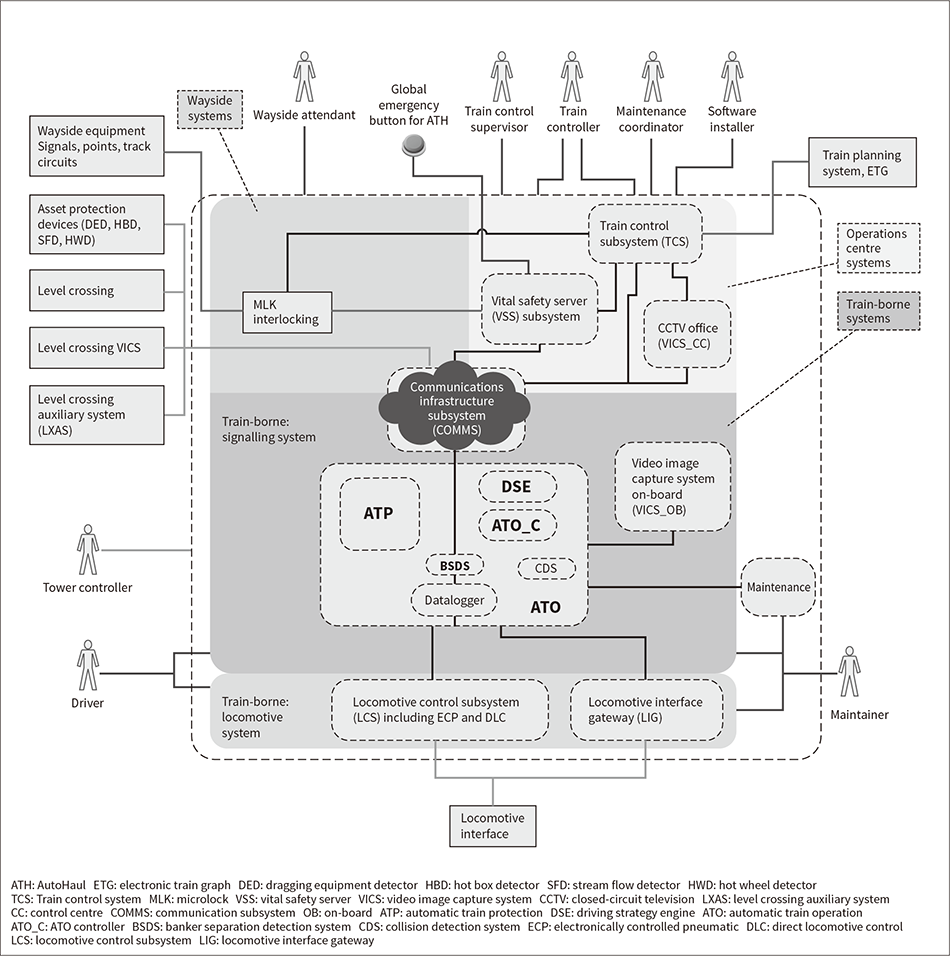

The Main Line computer system by Rail Vision should allow to recognize potentially dangerous objects (other trains, arrows, people, vehicles, etc.) and evaluate the rail traffic situation. The data received from the sensors is processed using AI tools. Rail Vision claims the Main Line system can detect vehicles up to 2 km, people up to 1.5 km, and the end of tracks up to 600 m in any weather condition and times of day. Hitachi Rail STS declares the highest GoA4 level of automation in AutoHaul, however, there is a driver on board, who, together with the dispatch center, is warned by the system about the critical situations.

Rio Tinto has about 220 diesel locomotives of four series manufactured by GE (acquired by Wabtec) that transport iron ore from 16 mines to the ports of Dampier and Cape Lambert on a network of more than 1,700 km in the Pilbara region. The entire AutoHaul system complex cost is $940 mln USD. Currently, the total mileage of automated rolling stock has exceeded 4.5 mln km. Rio Tinto claims that AutoHaul introduction helped to increase the average speed of locomotives by 5-6%.

Structure of the AutoHaul system (enlarge). Source: Hitachi STS

Structure of the AutoHaul system (enlarge). Source: Hitachi STS

Rail computer vision systems are now being tested all over the world. Thus, in May, a consortium of German companies with the participation of Siemens Mobility and under the leadership of Deutsche Bahn (DB) launched the second stage of the Sensors4Rail project as part of the Digitale Schiene Deutschland (DSD) program in Germeay. Within its framework, during 1.5 years, it is supposed to check the efficiency of the computer vision system installed on electric trains in Hamburg in different operating scenarios, as well as the accumulation of data from sensors for further training of neural networks.

Also in April, Alstom announced trials of the AutoPilot computer vision system at the shunting in Netherlands. The Lineas operator and the ProRail national infrastructure company also participate in the project. It is stated that the system already allows to detect obstacles of any size at a distance of up to 1 km in all weather conditions, day and night. Earlier in 2021, it was also reported that Thales’ computer vision system trials are being conducted jointly with SNCF and Alstom in France. The completion of unmanned shunter with the VTT computer vision systems was recently announced in Finland.

Bombardier Class 474 electric train equipped with computer vision system as part of the Sensors4Rail project. Source: digitale-schiene-deutschland.de

Bombardier Class 474 electric train equipped with computer vision system as part of the Sensors4Rail project. Source: digitale-schiene-deutschland.de

Thales is also running computer vision system tests in Canada on Metrolinx trains with the InvisionAI startup. In Japan, a high-speed train with the GoA4 level of automation is being tested by JR East.

In Russia, the introduction of computer vision systems is being worked out both on electric trains and on shunting locomotives in Russia. Trials of the Lastochka EMUs with the GoA3 automation level have been carried out by Russian Railways (RZD) since 2021. At the same time, the NIIAS research center is working on improving ATO system to the GoA4 level with a plan for its certification in 2022-2023. The computer vision system installed on the train is already capable of detecting a 30 cm obstacle at a distance of 400 m, a person at a distance of up to 600 m.

As Pavel Popov, Deputy CEO of NIIAS and the technical head for unmanned train projects in RZD, told to the Gudok newspaper, the automatic calibration for computer vision systems is currently in deployment. The cameras, lidars and other devices checks and adjustments will be carried out automatically when the train enters the depot. Pave Popov notes, that such a calibration system is being created for the first time in the world, and Russian ATO developers are “at least a year and a half ahead of leading European manufacturers implementing the same project”. The decision to put fully GoA4 trains into operation should be made by RZD in 2023 based on the results of trials.

ChME3 locomotive with the Cognitive Rail Pilot vision system installed on it. Source: Cognitive Technologies

ChME3 locomotive with the Cognitive Rail Pilot vision system installed on it. Source: Cognitive Technologies

Another Russian company, Cognitive Pilot (a subsidiary of Sberbank and Cognitive Technologies), together with RZD, completed testing of computer vision system for shunting locomotives in January. It is stated that the system is already capable of recognizing objects at a distance of up to 300 m, but the company plans to increase this parameter by at least twice. The option of integrating the CTRL@VISION computer system of TMH Smart Systems is also supposed to be included in the new TEM23 shunting locomotive by Transmashholding: as to CTRL@VISION presentation, it is capable of detecting and classifying objects and obstacles at a distance of up to 250 m.