Russia: The diesel locomotive is currently undergoing trials and is planned to be certified in June. TEM23 is the first vehicle in the new Transmashholding (TMH) locomotives platform, which will also include alternative traction solutions.

UPDATED: The TEM23 diesel shunter received approval for operation at the end of December 2022. TMH is allowed to produce the pilot batch of 100 such locomotives.

The other day, the first two TEM23 locomotives produced by TMH at the Bryansk Machine-Building Plant (BMZ) have begun the final stage of preliminary tests. It will undergo an experimental 300-hour run in the Russian Railways (RZD) depot in the Bryansk region.

Depot employees are already positive about TEM23. According to driver-instructor Andrey Shchelokov, the four-axle TEM23 is capable of performing shunting operations with the same heavy trains as six-axle locomotives of previous generations. As the head of the BMZ testing group Alexander Protsenko points out, one of the vehicles has already hauled a 4,600-ton train, the other – a 6,000-ton train.

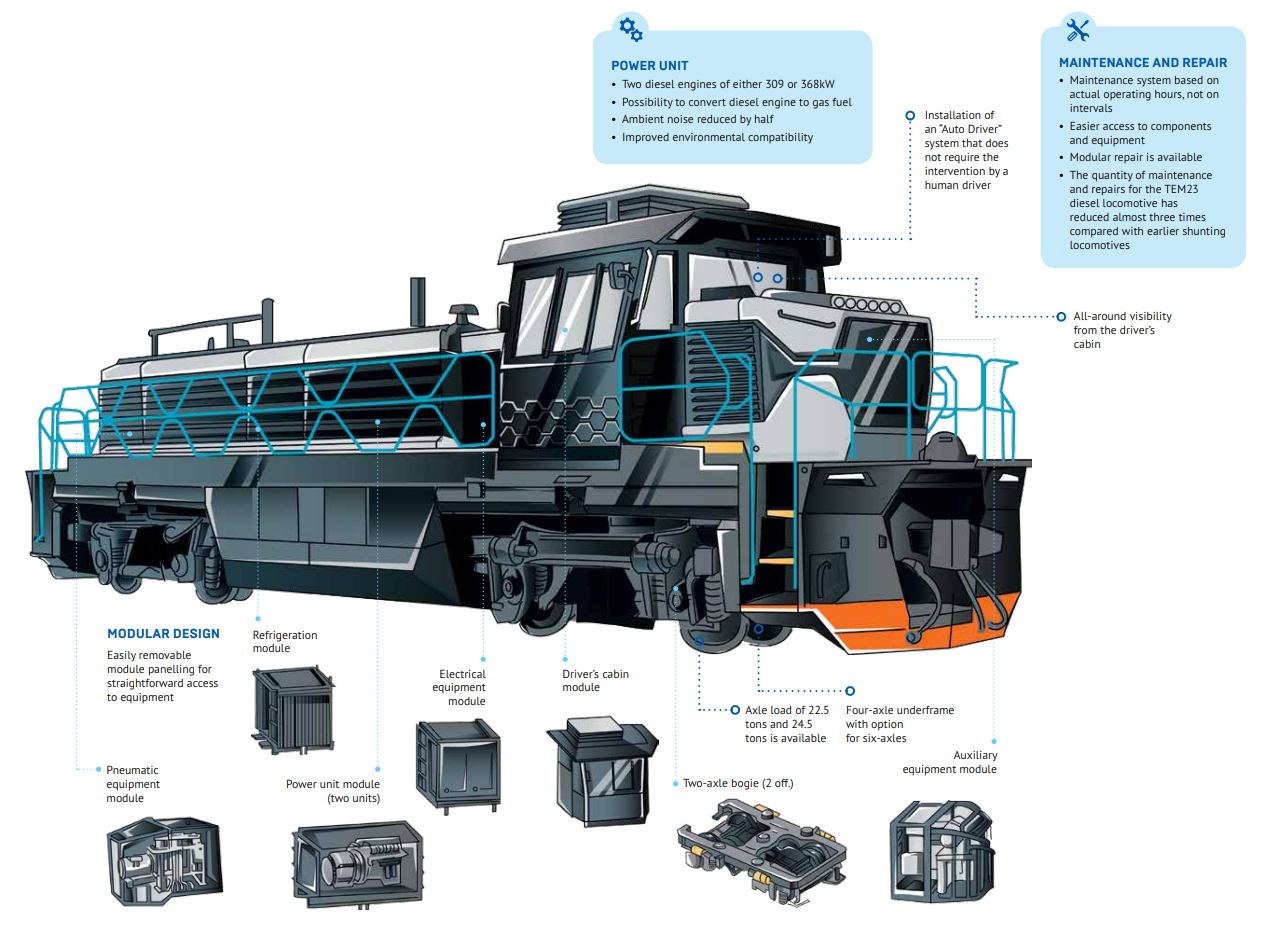

The TEM23 diesel locomotive was presented by TMH in August 2021 during the PRO//Motion.Expo salon in Russia. It has an asynchronous traction drive and two KAMAZ diesel engines inside with a power of 309 and 368 kW. Traction force when starting off was declared at the level of 300 kN. The use of two-axle bogies should allow TEM23 to pass curves with a minimum radius of 40 m, while it is possible to implement an axial load of 22.5 and 24.5 t.

The main technical solutions in the TEM23 locomotive (enlarge). Source: Vector TMH

The main technical solutions in the TEM23 locomotive (enlarge). Source: Vector TMH

In order to improve serviceability TEM23 has a modular design. Its layout includes interchangeable modules of the power units (2 pieces), pneumatic equipment, refrigeration, electrical equipment, driver’s cab and auxiliary equipment. TMH also announces significantly increased overhaul runs: according to the manufacturer, maintenance and repair costs will be 47% lower than for models in operation today. The design concept of the TEM23 exterior was awarded the Good Design Award.

As TMH CEO Kirill Lipa noted in an interview with the Railway Equipment Journal in the summer of 2021, TEM23 is a functional substitution for the previous flagship TEM18DM shunting locomotive model it has been produced since 2007, and the TEM18 platform itself has been produced by BMZ since 1992). At the same time, the new platform involves the development of a line of several vehicle modifications. It is planned to provide the possibility of converting diesel engines to gas fuel and the development of a six-axle locomotive version. The integration of the ATO systems into TEM23 is also expected. The technologies developed by LokoTech-Signal will provide three modes of operation: unmanned movement, obstacle detection and remote control.

TMH also notes the completion of BMZ production capacities modernization, which will allow the serial production of TEM23 to be launched. More than 1.7 bln RUR ($23 mln USD) was allocated for this project. The invested funds were used to purchase 20 units of equipment, including painting and drying booths, robotic welding complexes, machining centers and measuring instruments.

Additionally, TEM23 platform is the basis for the perspective EMKA2 shunting electric locomotive with hybrid traction from batteries and catenary. It is planned that the power on the shafts of traction motors in hourly mode from the catenary will be at least 500 kW, from the batteries – 300 kW. In early February, Pavel Morozov, TMH Director for Industrial Safety and Sustainable Development, pointed out that TEM23 and EMKA2 are the manufacturer’s major products in 2022. TEM23 certification is expected in June this year. One of the tested vehicles is already painted in RZD corporate colours.

TEM23 diesel locomotive in RZD corporate colours, September 2021. Source: Alexey Likhachev, trainpix.org

TEM23 diesel locomotive in RZD corporate colours, September 2021. Source: Alexey Likhachev, trainpix.org

On the Russian market, the TEM23 locomotive will compete against the TEM10 four-axle locomotive manufactured by Sinara Transport Machines (STM) at the Lyudinovo Diesel Locomotive Plant. It was certified in November 2020. Just like the vehicle from TMH, the TEM10 locomotive has a modular design with a two-diesel installation: currently it is being equipped with Volvo engines of 428 kW power, thus the option of installing Russian-made diesel engines is being worked out. Traction force when starting off is declared at the level of 291 kN, the minimum radius of passable curves is 40 m. At the moment, 7 TEM10 locomotives have already been delivered to NLMK, MMK and other customers. According to open data, STM’s portfolio of orders currently includes the production of another 5 such locomotives for MMK and Evraz.