Russia: The company reported having delivered the first pilot batch of 1,000 wheels to Russian customers, however, no details about them are available.

The wheels of new design have been in development since 2020. To manufacture the product, a new grade of steel, V, heat treatment modes, and resurface software for CNC machines were also developed.

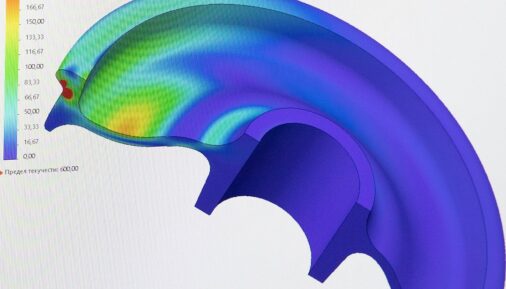

According to EVRAZ, wheel weight has been reduced by 8% compared to existing models, resulting in a 0.2 t increase in car payload. Previously, the company announced the wheels are designed to cater primarily to freight cars with an axle load of 25 tf and boast an operational life of 1.0 mln km.

The company states that the axle load on the new wheels is absorbed evenly and distributed across the entire disc cross-section. “The wheels have a Brinell hardness of at least HB 360, which is almost equal to that of rails. This has resulted in a 30% increase in wear resistance”, as explained by the company.

EVRAZ reports that the wheel, which has already been patented, was tested at the VNIIZhT railway research institute’s test track. However, the TR EAEU 001/2011 certificate for the wheel could not be found, and there is no information available on the production site. The new wheels can be produced at either EVRAZ’s Nizhny Tagil Iron and Steel Works or a new site, Allegro in the special economic zone of Verkhnyaya Salda, Russia.

Also, the company received a certificate in March to produce 1,082 mm diameter forged wheels made of T steel, specifically designed for the bogies of Sinara Transport Machines’ promising the 2TE35A mainline diesel locomotives.