Russia: Hydrogen fuel cells, powerful Li-Ion batteries and synthetic fuel have supplemented the list of the technologies previously approved by the Russian Government for concluding of the Special Investment Contracts (SPIC).

SPIC is an instrument of the Russian state industrial policy and assumes that the investor entering into a contract with the government sets up the production of the required products and receives various support: tax benefits, preferences in public procurement and land leases. Contracts are to be concluded for a period of up to 15 years if the project investments don’t exceed 50 bln RUR (approx. $0.67 bln USD). With a larger amount, the agreement can be extended to 20 years. The original list, approved in November 2020, included 630 technologies, more than 80 of which have been added by a new government order.

According to the document, SPIC may be concluded for the development of hydrogen fuel cells production technology with a capacity of 10 kW or more with the possibility of its modular design (execution). The period of relevance for mastering the technology is up to 2040.

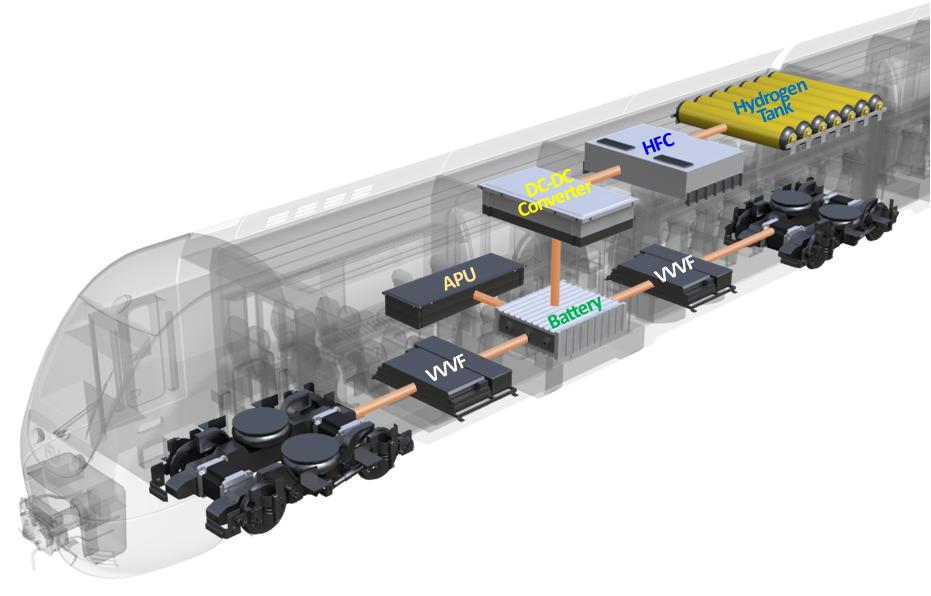

In Russia, work on hydrogen propulsion is carried out by the two largest rolling stock manufacturers – Transmashholding (TMH) and Sinara – Transport Machines (STM). TMH is developing a hydrogen train based on the Orlan DMU (Russian Railways plan to launch a trial operation of it in 2023), and STM is developing shunting and mainline locomotives with a plan to release prototypes in 2026-2027. In November, STM reported having near-term plans to model an integrated drive using hydrogen propulsion systems.

Also, the Russian Government can conclude SPIC on the development of lithium-ion batteries technology for traction systems. The document establishes various parameters of the minimum specific energy (from 120 Wh/kg), specific power (from 900 Wh/kg) and energy density (at least 300 Wh/L per cell), depending on the requirements of technical equipment, which is supposed to be equipped with the batteries. Electric transport is indicated to be one of the target areas for the use of such batteries. The period of relevance for mastering the technology is until the end of 2040.

Recently, STM has announced works on the battery version of the Lastochka EMU. As part of the Sinara Public Talks meeting, the head of the project management center of Ural Locomotives (a joint venture of the Sinara Group) Grigory Golubev said that R&D works on the traction system is planned for next year; a prototype battery train is expected in 2023. In turn, TMH is developing an EMKA2 shunting electric locomotive with traction both from batteries and from a contact network: its commissioning is scheduled after 2023.

The third technology that is relevant to the rolling stock traction, approved for development under the SPIC, is the production of synthetic motor fuel from gas. It is assumed that two stages of its production will be introduced: the first is the production of synthesis gas from methane or associated petroleum gas, the second is the conversion of synthesis gas into fuel. A condition has been established that the unit capacity of one technological line created by the investor must be at least 1 mln tons per year. The development relevance period is set for 2045.

As the president of the Russian Union of Industries of Railway Equipment (UIRE) Valentin Gapanovich noted, in the medium term, synthetic fuel can be a good solution for the rolling stock traction, both in terms of cost and harmful emissions. “Its use will mostly allow preserving the Russian Railways’ refueling complex and require only minor modernization of diesel engines fuel injection equipment”, he said in an interview with the Railway Equipment Journal.