Russia: The last 2021 year brought about dramatic challenges. We witnessed pandemic risks peaking, prices for raw materials and components soaring, customer investment plans revised and adjusted. All things considered, the mechanical engineering industry cannot but boost efforts aimed at securing performance improvement. Sinara Transport Machines (STM) has been implementing such a program since 2018, with its efficiency yielding better results every year.

Large-size holding production requires harmonized planning and manufacturing. By coordinating interrelated business processes, we achieve synergy and secure greater economic effect. The STM performance improvement program encompasses 9 manufacturing sites, 12 production lines and nearly 10,000 employees, as well as involves 385 project teams consisting of managers and blue-collar workers.

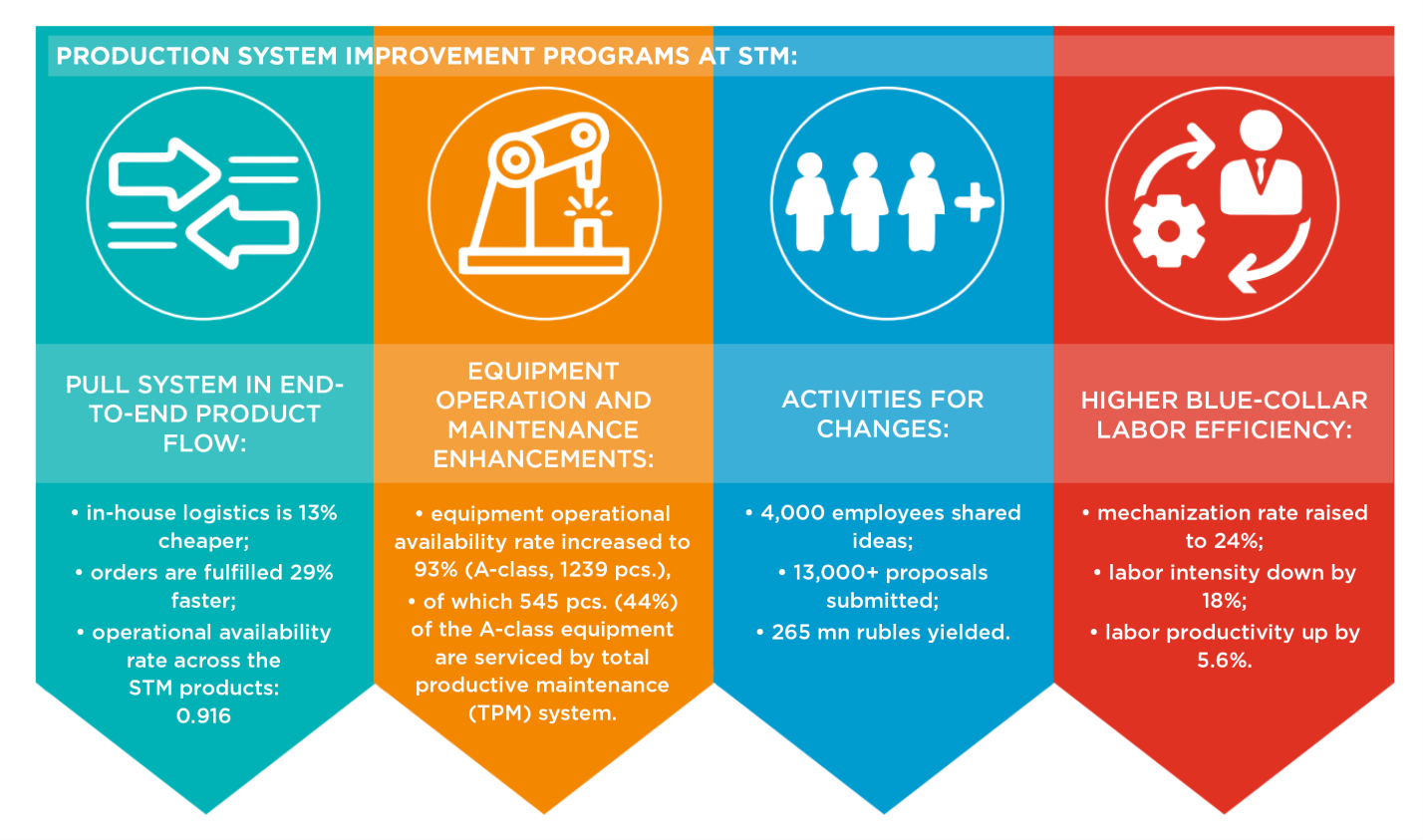

Last year the pull manufacturing system continued to be implemented in the workflow across the STM enterprises. It suggests supplying components for each of the technological operations as needed, within a strictly scheduled period, thus avoiding overloaded storage facilities and reducing manpower and equipment downtime periods. As a result, in 2021, we managed to cut our in-house logistics costs by 13%, while speeding order fulfillment up by 29%.

We have introduced a total productive maintenance (TPM) system enabling the safe and correct machinery maintenance ensuring its continuous operability without having to engage servicemen. It is a training course on the SOTA2U corporate portal that helped operators master it.

Novosibirsk Electric Locomotive Building Plant is among the trailblazers spearheading the advanced manufacturing practices at STM in 2021. Source: Kirill Kuhmar, TASS

Novosibirsk Electric Locomotive Building Plant is among the trailblazers spearheading the advanced manufacturing practices at STM in 2021. Source: Kirill Kuhmar, TASS

The TPM system deployed across all STM sites covers 523 units (42%) of the critically important A-class equipment. The lean manufacturing approach made it possible to identify 1,676 pieces of unused equipment in 2021. This allowed us to write off and sell 670 machines, with the earned 67.1 mln RUR ($0.9 mln USD) invested in the production development.

Note that the optimization benefitted both the machinery and workflow: the workload beyond value-added activities (like waiting for the supplies of raw materials and consumables, machine idle times to replace parts etc.) was reduced by 38.9% on average across the STM sites, which increased the value of each worker’s labor.

This was in no small part facilitated by advancements in the working conditions for the holding’s blue collars. The overall mechanization rate has increased from 12 to 24%, with work places upgraded, component and tool storage areas rearranged, and extra manual equipment and carts purchased. As many as 164 technical issues were sorted out through the Theory of Inventive Problem Solving (TIPS). Eventually, all these innovations helped reduce the labor intensity by 18% and increase labor productivity by 5.6%.

This was augmented by multiple product quality improvements with 19 technological processes streamlined. It took us a little over a year to ensure seamless operation of the “Quality Gate” system, introduced in 2020. This system enables an expert team to analyze and verify whether the product is finished and complies with the specified requirements while it is still at certain manufacturing stages. Only after the product meets all the criteria it passes on to the next stage. Otherwise, it is sent back for rectification. By detecting faults at the earliest stages of production, the system allows saving time on rectification. As a result, in 2021 the operational availability rate across the STM product range rose by 6.4% year-on-year and amounted to 0.916.

It would be impossible to achieve such impressive progress without involving the staff in improving the production system. That is why for more than two years now we have been encouraging innovative ideas from employees. The 2021 result: over 4,000 employees shared 13,000 ideas. As much as 67% of proposals were greenlighted and implemented, which is 2% more than in 2020, from minor modifications to a large-scale facility construction. Overall, the introduced innovations yielded over 265 mln RUR ($3.6 mln USD), which is 15 mln RUR more than planned. The released funds are invested in the production development.

As an incentive for rationalization, the “Idea Champions” contest has been held among the authors of the best proposals for the second year running. The continuously evolving culture of manufacturing process improvement and development is also worth mentioning. Last year its index rose by 10 points and now stands at 54%. Another important thing is that we have accumulated a sizable knowledge base over a few years of the Efficiency Directorate’s work. These tutorials will be of help for both those employees who have already received training in lean technologies, and those willing to familiarize themselves with the topic. The entire knowledge base and a remote course are available to the employees on the corporate portal.

The year 2022 has brought about even harder challenges putting us all to a real stress test. The holding’s enterprises keep pursuing the following aims:

- Meeting tighter deadlines. Schedule compliance has to be ensured at least in 95% of cases.

- Streamlining the cycle. Orders have to be fulfilled 20% faster.

- Enhancing the flexibility. Faster manufacturing chain redistribution in response to changes in the market conditions.

Furthermore, the “Activities for Changes” program provides for initiatives such as “Idea Foundries” deployed at enterprises with a view to encouraging the employee involvement.

And last but not least: new models have to be launched for production. As many as seven projects are well underway for all of our new products for 2022. The phase-gate system involving multiple decision points enables quick start-ups, lower accompanying project-related risks, early error detection/prevention and less follow-up rectification.

The results of 2021 prove that manufacturing enhancements are rewarding and thus worth making efforts. However, both the customer requirements and the current corporate agenda keep changing, so there is still a lot to be done: adjusting the workflow procedures to new requests, arranging advanced training and competency enhancement for the personnel etc. Still, nothing motivates you to progress better than new challenges.

Author: Elena Dolganova, Deputy CEO for Performance Management, Sinara Transport Machines

Based on a feature article on the Manufacturing Process Management portal (up-pro.ru) dated May 16, 2022