Indonesia, Russia: In October 2022, Unitsky String Technologies (UST) and ITS Indonesia, a non-commercial organisation, signed a memorandum on the development of string transport systems in the country. One proposed project will build a track about 8 km long in its capital, Jakarta. This March, the governor of a Russian region, Leningrad oblast, Aleksandr Drozdenko announced in his Telegram channel the start of work on a regional string transport BOT project. Later in April, the technology was offered to representatives of the government of Yakutia and the mayor’s office of its capital. At the same time, the string transport only exists within test sites in Belarus and the UAE. Although the concept was developed more than 40 years ago, only in 2017 its testing began and in 2022 it obtained a TUV SW certificate. Both the design solution and financing mechanism of the string transport have been criticised for a long time.

The idea and principles of the technology

Its inventor, Anatoli Unitsky, now the chairman of UST board of directors, began elaborating the idea of string transport in 1977. It was then that he began a sketch engineering design of a self-moving passenger car with rails vertically arranged in a prestressed track structure.

The key element of the system is a string rail. It is an ordinary beam or truss made of steel, reinforced concrete, or steel-iron concrete uncut lengthwise, with a bundle of pre-stressed wires in its core. The horizontal load is borne by the anchoring structures installed up to 10 km apart, and the vertical load is distributed on supporting towers installed up to 2 km apart.

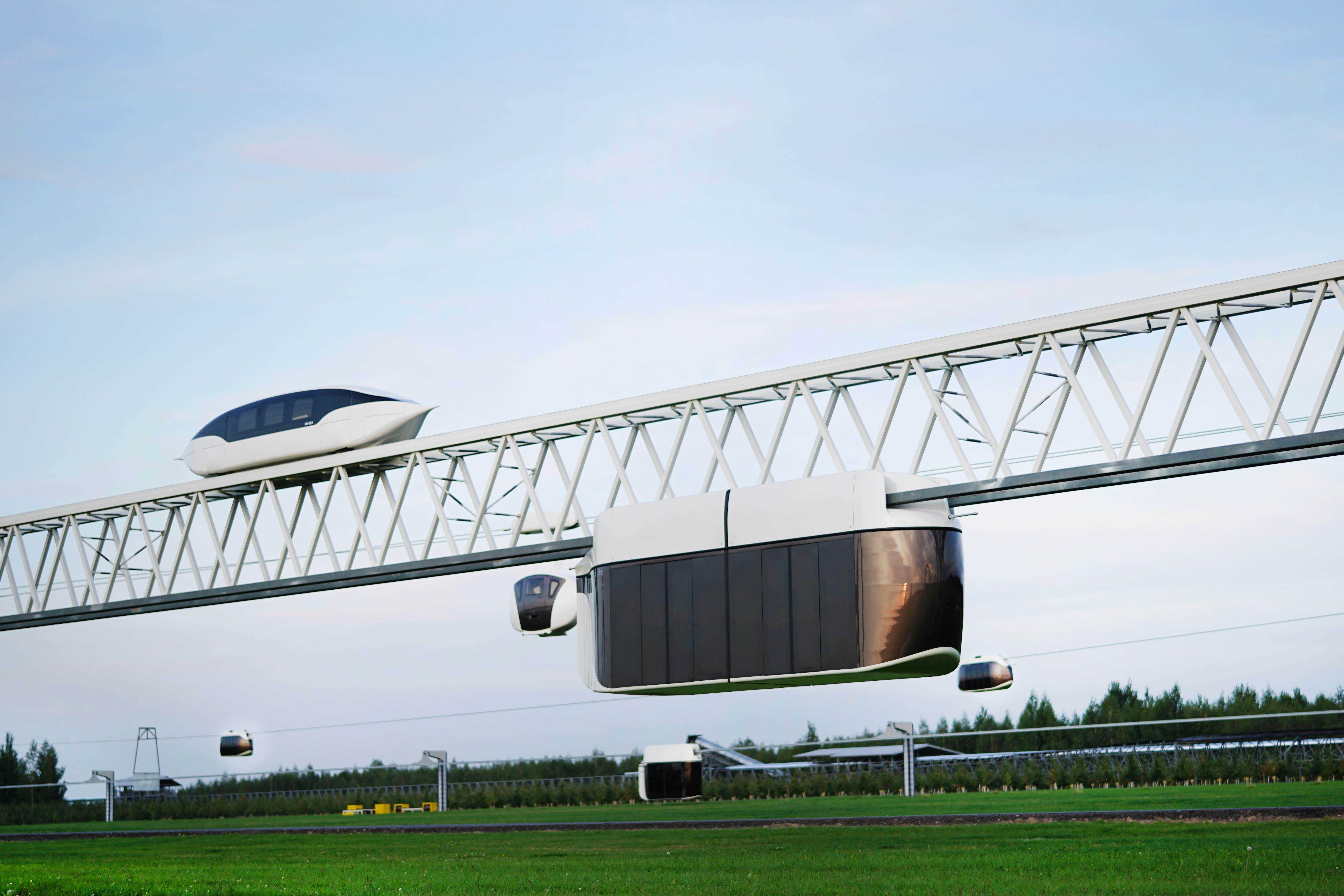

Suspended from a rail, the vehicle autonomously moves by means of steel wheels. By now, more than a dozen “electric rail vehicles” have been developed. They accommodate from 2 to 90 passengers and are claimed to have a design speed of 150 km/h. The passenger vehicles are univind, unicar, unibike, unibus, unilight, and freight ones are unitruck and unicont. The rolling stock consists of three main modules: a synchronous traction motor, a functional module (cargo, passenger, or cargo-and-passenger), and an onboard control.

UST’s booklet says string tracks will have special switches, and before major stations, high-speed switches well over 100 m long designed for speeds of up to 200–350 km/h for the through traffic.

Unilet, unibus, and unicars on the track at EcoTechnoPark. Source: unitsky.engineer

Unilet, unibus, and unicars on the track at EcoTechnoPark. Source: unitsky.engineer

When referring to the cost of construction, UST applies an integrated index calculated by the Institute of Transport Problems of the Russian Academy of Sciences. With this approach, the cost of a string system would be half of that of a railway system, 12 times lower than a monorail, and 18 times lower than a maglev. The estimated cost of transportation, according to UST, will be 3–5 or even more times lower.

Pilot projects

The implementation of a string transport project began in Russia, in the suburbs of Moscow. In 2001, the first test bench was launched in the town of Ozyory. The 150 m long construction has supports of up to 15 m in height, a maximum span of 48 m and a rolling load of up to 15 t. A ZIL-131 truck is used as rolling stock, with steel wheels adapted for the string-rail track. To manufacture a string-rail system, supports, freight and passenger rolling stock, comprehensive tests produced data for design and exploration.

String test site for Unitsky transport at Ozyory. Source: yunitskiy.com

String test site for Unitsky transport at Ozyory. Source: yunitskiy.com

After the launch of the bench and before this year’s news, the ones that attracted the most attention were activities to introduce the technology in the Ulyanovsk region. In 2009, Unitsky String Transport and the regional government signed an investment agreement. Construction of a test site and an educational facility for future string transport specialists was expected to begin in the region. The project was later frozen, with its resumption discussed in 2017. The company obtained certificates from the Russian Research Institute for Urban Electric Transport for a passenger unibus U4-210 and a cargo unibike U4-62, although they expired in 2020. Now, no data on their renewal is in the public domain, and the project is not developed anymore.

UST’s greatest success to date was achieved in Belarus and the UAE. In 2017, a test site, EcoTechnoPark, was launched in the town of Maryina Gorka about 70 km from Minsk. In a plot of 36 hectares, the company built five various transport and infrastructure complexes, stations, depots, and other infrastructure facilities. According to UST, 12 models of string vehicles have already been tested there. 2017 saw a record when a unibike reached 102 km/h on an 800 m light urban track. The company states, however, that the vehicle cannot reach its design speed of 150 km/h even on the longest track of 950 m available in EcoTechnoPark. To conduct such tests, a 2.4 km long track is built in the UAE now.

Bird’s eye view of EcoTechnoPark, 2021. Source: unitsky.engineer

Bird’s eye view of EcoTechnoPark, 2021. Source: unitsky.engineer

The second UST test site, uSky Test & Certification Centre, was opened in STRIP, a Sharjah-based technopark. Now, only a test track of 400 m operates there since 2021 when the centre was launched. Although the track is much shorter than those in EcoTechnoPark, it was the first in the company’s history to obtain a TUV SW certificate together with a unimobile.

uSky Test & Certification Centre in Sharjah. Source: uST Technology/youtube

Today UST claims to be building another 2.4 km test track for a 25-seat unibus and a unicont with a capacity of up to 35 t. According to the company, the track integrates passenger and cargo modules in the same network and allows testing them at a design speed of 150 km/h.

Uncertainty about technology and financial fraud

Unitsky believes the most intricate and at the same time one of the most promising areas is high-speed transport and infrastructure complexes where speeds of up to 500 km/h are achieved. In late 2021, he stated: “If plans come to fruition, we will launch them on the global market by 2025”. For information: countries like Australia, India, Indonesia, Italy, and Lithuania entered into negotiations with SkyWay, but later security concerns and financial improprieties led to cancelling or shelving the plans.

The design solutions of the company have been criticised more than once. In 2008, the Russian University of Transport analysed the technology and concluded that it has “numerous system weaknesses” and is impractical “as it does not offer a clear passage for traffic”.

In 2017, the Belarusian portal Onliner.by asked the country’s scientific community for their opinion on the technology. The Belarusian State University of Transport doubted string transport could achieve speeds exceeding 300 km/h. Its experts stated the theory allows only certain aspects of the string to be applied. They stressed that cargo and passengers, for example, could be transported at speeds of up to 100 km/h but not 500 km/h, and the interaction dynamics of a transport module and overground structures remained untested.

The National Academy of Sciences of Belarus emphasised insufficient elaboration of the project in terms of science, technology, and economic efficiency compared to traditional systems. Nevertheless, last April, both the academy and the state committee on science and technology of Belarus issued an accreditation certificate that allows Unitsky String Technologies to engage in scientific activities for five years.

Mistrust is reinforced by information on the funding models used in the project. Many media and the expert community describe the company as a pyramid scheme. The article Onliner.by published in 2017 identifies three fundraising stages. While physical persons are sold shares in the company, Onliner.by claims they obtain only “certificates” confirming their right to shares. People also could enter into secured contracts or consulting agreements. The money received is transferred to accounts of offshore companies registered in the British Virgin Islands, and then to accounts of Unitsky String Technologies as an increase of share capital by the founder, loans, or payments under consulting agreements.

It is not possible to find out until when the financial scheme was in use. Now, the website of one of the companies that raise investments to UST offers a convertible loan agreement. It is stated that upon request an investor can immediately receive a share in ERSSH III which is declared to be a shareholder of GTI, a company owing the string transport technology. If investors do not request their share, the money is considered a loan, and they can get it back within three years with a return of up to 4%.

When asked about the funding model of the project in November 2021, Anatoli Unitsky explained that most of the funding is raised through crowd-investing and argued that all the responsibility rested with non-affiliated independent companies and enthusiasts. He described the model as highly effective but acknowledged that it resulted in restrictive measures against the company in many countries. By now, Indonesia, Belgium, Czechia, Estonia, Italy, Latvia, Germany, New Zealand, Greece, and Slovakia already warn their citizens about the dangers of investing in UST as its financing scheme is opaque. Some of these countries have even banned activities of the company.

According to Unitsky, UST specialises in engineering and science and no claims or prohibitions have ever been made against it. However, the companies that raised funds for the project offered investors unrealistic short payback periods, misinformed them, made empty promises, and that cast a shadow over the company. Unitsky stresses the financial and legal independence of UST from these companies which either existed earlier or operate now and emphasises that his company cannot be held liable for their methods. At the same time, they continue to be partners.