Russia: The mainline freight locomotive is certified to TR EAEU 001/2011, which means that the vehicle manufactured by the Bryansk Engineering Plant, a part of TMH, can now be used in the territory of the EAEU countries – Armenia, Belarus, Kazakhstan, Kyrgyzstan and Russia.

The pilot batch will consist of up to 400 three- and two-section diesel locomotives. In February, Russian Railways has announced its plans to buy 30 of these locomotives this year.

The 3TE28 diesel locomotive is designed for hauling trains of 7,100 t on the sections of the Baikal-Amur Mainline and Trans-Siberian Railway with rugged terrain, and of up to 18,300 t on the plain. In last year’s tests it managed to haul train-sets of 7,256 t.

The manufacturer has introduced the 8,550 kW 3TE28 locomotive in August 2022 as a replacement for the previously produced 3TE25K2M with GEVO12 power plant by Wabtec. The new locomotive uses the 18-9DGM diesel generator developed by TMH’s Engineering centre for diesel engine development. The generator is claimed to consume 10% less diesel fuel and oil and to comply with Stage IIIA emission standards.

The possibility of using vacuum contactors from the Cheboksary Electrical Apparatus Plant for the locomotive control rooms is now being considered. Previously, the 3TE25K2M locomotives were equipped with Secheron contactors. Prototypes and a pilot batch were delivered to the Bryansk plant in the spring of 2023.

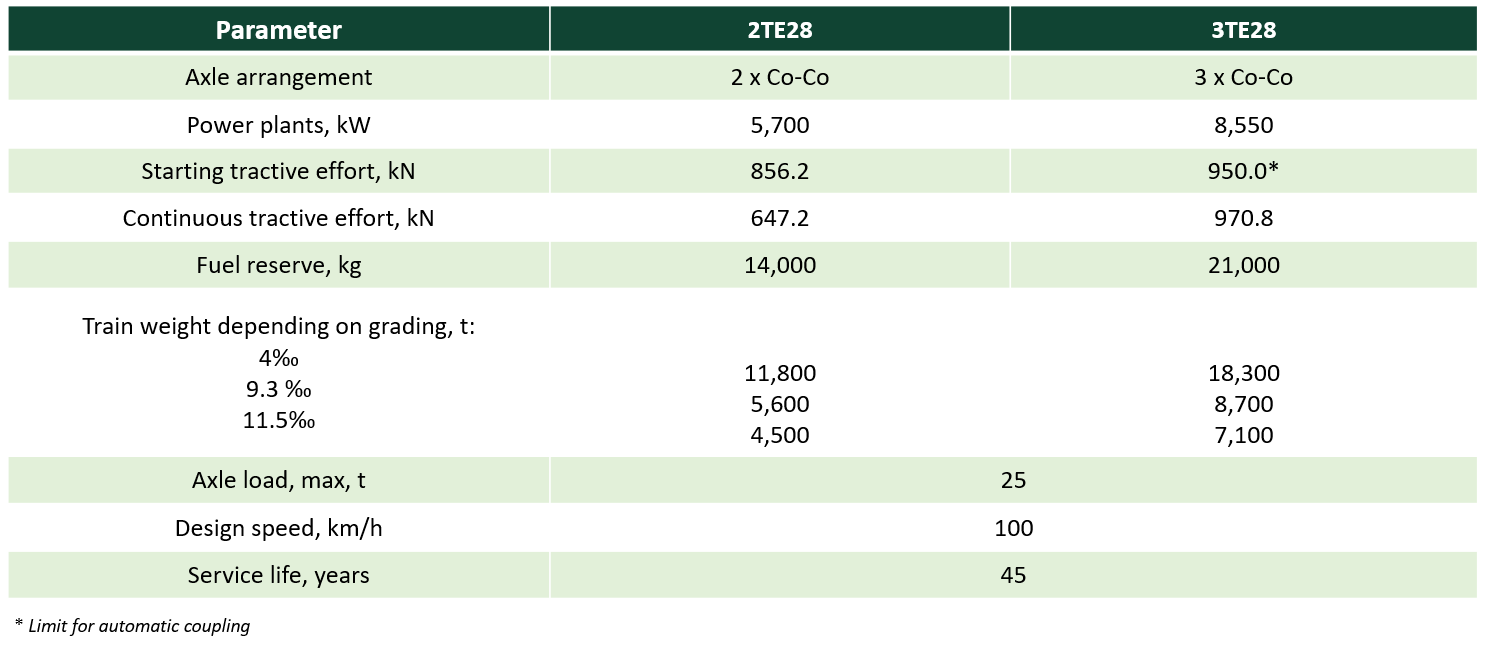

Key technical characteristics of the 2/3TE28 diesel locomotives (enlarge). Source: TMH

The locomotive is designed for multiple unit operation and allows asynchronous loading of sections. According to TMH, maintenance and repair of the 3TE28 cost 25% lower due to longer overhaul periods compared to the commercially available 2TE25KM diesel locomotives. These periods are partly extended by the use of a modernised engine. The 3TE28 must be maintained every 240 hours. In accordance with Russian standards the maintenance works include inspection of the running gear, brakes, traction motors, transformers, and electrical equipment. When it comes to repair, every 1,200,000 km works are carried out to keep the locomotive in good working orders and partially restore its service life, and it takes twice as much until the overhaul.