China: The 28.8 MW 24-axle six-section locomotive develops starting tractive effort of 2,280 and continuous tractive effort of 1,596 kN reaching 120 km/h. Its official operation began in June 2021. The new vehicle tripled volume of coal cargo service in Shanxi and Shaanxi, increasing it by 25 mln tonnes annually.

CRRC developed Shen24 under a contract with CHN Energy, China, for supply of 8 such electric freight locomotives. Another contract for 12 locomotives could be expected later. The rolling stock is intended to carry 10,000-tonne trains at 266 km route between Shenmu and Shuozhou with slopes up to 12‰.

At the end of July 2020, the first electric locomotive rolled off the lines of the Zhuzhou plant. The locomotive is based on the HXD1 two-section electric locomotive which been manufactured since 2006. According to CRRC, 16 innovative technological solutions are used in the new locomotive, making it the locomotive combining several global records. It is the longest electric locomotive with the largest number of axles and the highest capacity and tractive effort. Many of its components are made of composite materials, which means they have reduced weight and increased durability.

Electric freight locomotive Shen24. Source: Weibo

Electric freight locomotive Shen24. Source: Weibo

The test operation of Shen24 was at a test loop near Beijing. The vehicle has successfully passed 33 standard tests, including, those for braking performance and locomotive control system. Preliminary operation showed that the vehicle is capable of hauling trains up to 11,700 tonnes at slopes up to 12‰ and passing curves with a radius of 500 m. The trainset of 108 C80 open cars is 1,455 m long plus 106 m of the locomotive. The new vehicle started cargo service in June 2021 and covered more than 250,000 km by September 2022.

Driver’s cabin at electric freight locomotive Shen24. Source: sasac.gov.cn

Driver’s cabin at electric freight locomotive Shen24. Source: sasac.gov.cn

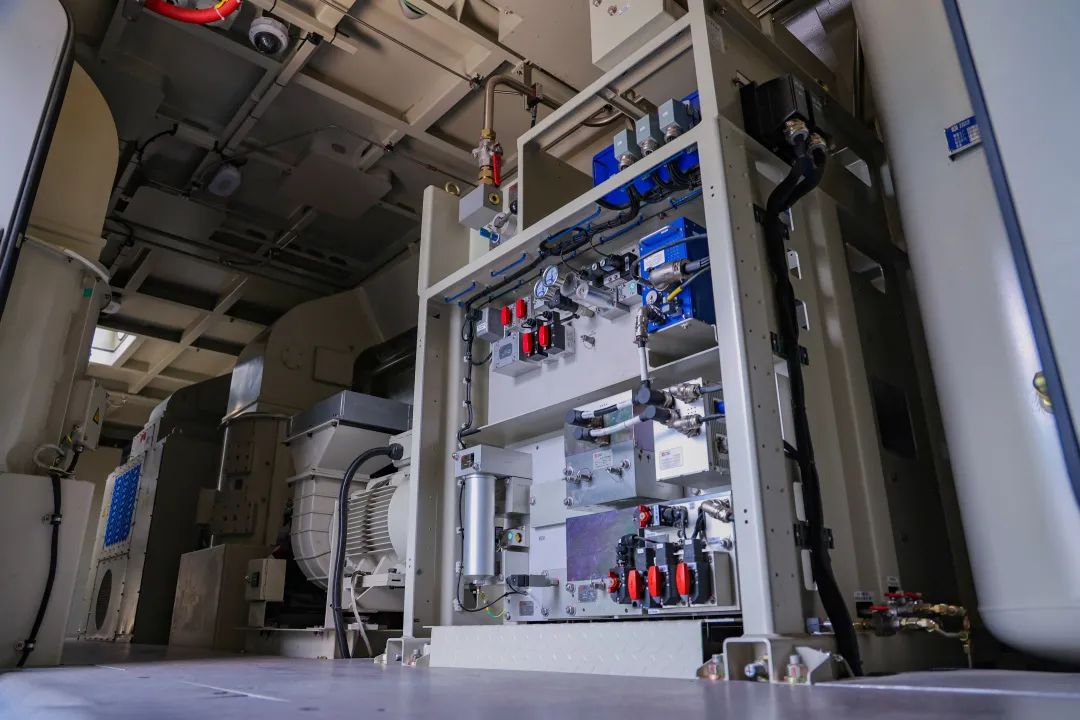

Engine room of electric freight locomotive Shen24. Source: Weixin

Engine room of electric freight locomotive Shen24. Source: Weixin

The vehicle employs a variety of digital solutions. It has a real-time component condition monitoring system and a component failure prediction system. Control of temperature and vibration deviations helps detect failed component. The automated train operation is responsible for starting, taking off, braking, and maintaining a required speed, so a single driver can operate the locomotive. However, there are two seats in the cab. The vehicle uses Beidou navigation satellite system, China, that can operate in a stand-alone mode if electric lines or pantographs are out of service.

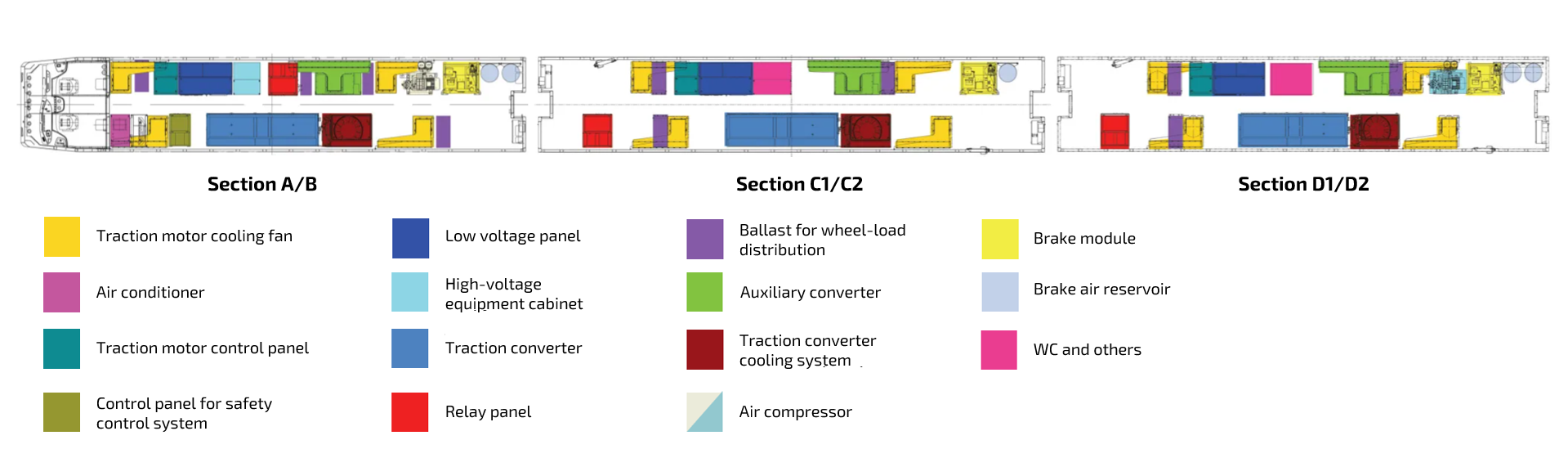

The standard design of Shen24 has six sections (A+C1+D1+D2+C2+B). The driver’s cab with the control panel is in A and B sections. Pantographs are located on the roof of inner sections D1 and D2 and outer sections A and B.

Layout of Shen24 sections (enlarge). Source: zhihu.com

Layout of Shen24 sections (enlarge). Source: zhihu.com

According to Wang Wei, head of R&D at the Zhuzhou plant, Shen24 is the first locomotive having a decentralized energy system. Usually, a locomotive has only one pantograph, so it distributes power to other sections with the help of a high-voltage jumper on the roof. In case of Shen24, four sections have pantographs, so no power distribution is needed. The dynamic battery balancing system allows the network control system to automatically recognise whether locomotive has four, five or six sections. The innovative converter power module solves technical problems such as boosting voltage or current division while in operation. As a result, the traction system of the new locomotive is more reliable and easier to maintain. The recuperation system uses ultra-high kinetic energy generated while applying the brakes.