USA: OptiFuel Systems has announced the development of a 4,100 kW locomotive powered by renewable natural gas (RNG) from bio-waste with a specially designed 1,850 kW tender with a 28 m3 DGE capacity.

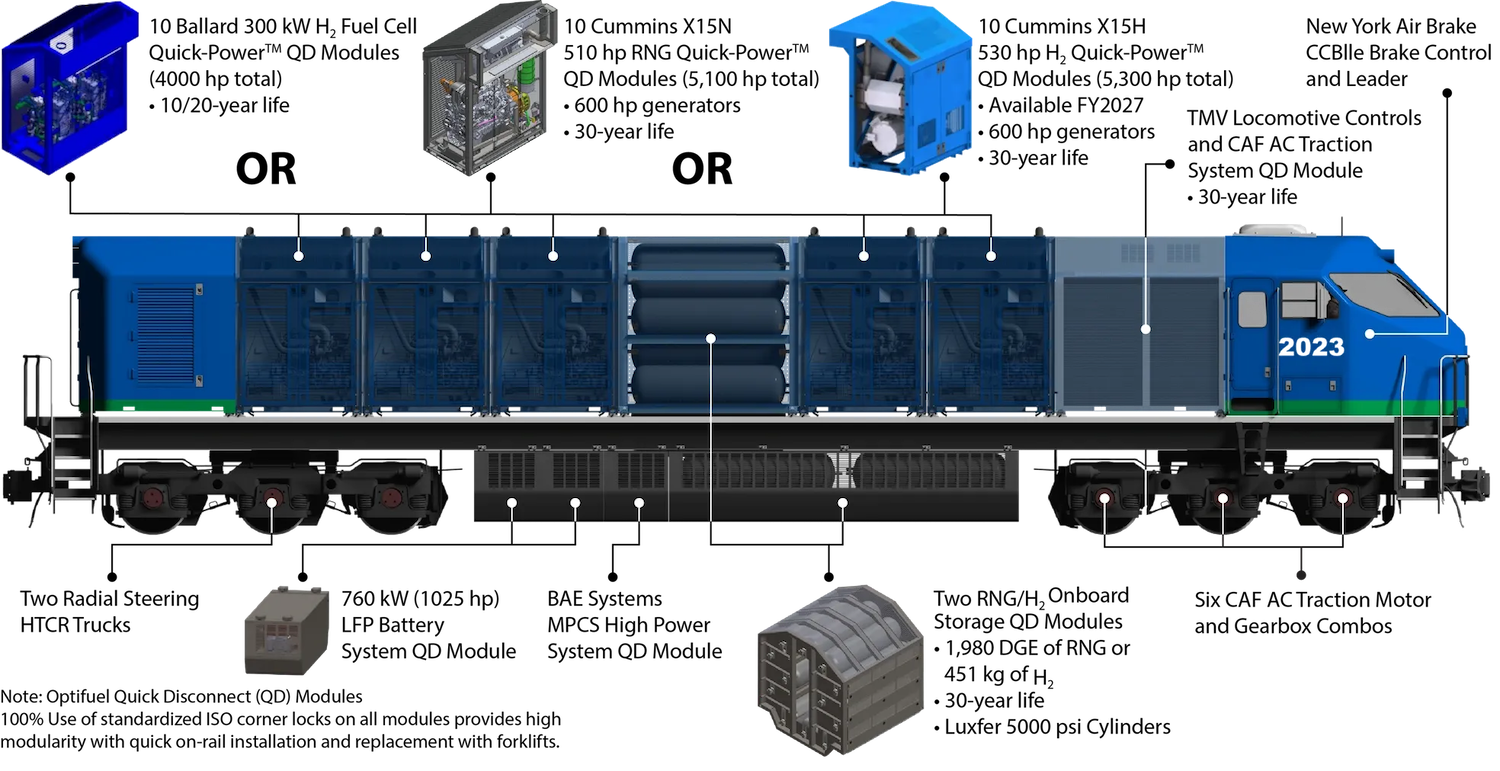

The key feature of the locomotive under development is its modular design. The vehicle is assembled using Quick Disconnect (QD) modules with standard ISO corner locks on the frame. The modules, with different power units, gas cylinders, traction converters, and auxiliary traction battery packs, can be installed or replaced using a conventional forklift truck. Such an approach is said to have the important advantage that almost 90% of the components are interchangeable between different types of locomotives, from small shunters to mainline locos. According to OptiFuel, the standardisation and high volume production combined with this approach would simplify servicing and reduce the maintenance and overall cost of the locomotive.

The locomotive will have ten OptiFuel Quick-Power modules available in three variants:

-

- 375 kW Cummins X15N RNG engines;

- 300 kW Ballard hydrogen fuel cells;

- 390 kW Cummins X15H hydrogen engines.

The company is now implementing the first option. As Scott Myers, CEO and President of OptiFuel, explains, their decision was based on the experience of converting diesel locomotives to hydrogen for Sierra Northern Railway in California, USA. “We now believe that RNG is the preferred path to zero-emission line haul locomotives and tenders due to the physics of energy storage, overall operating cost, operating risk, fuel availability and cost over the next 20 years. A 4,500 hp line-haul locomotive requires continuous high power for extended hours, something that neither battery-electric nor hydrogen fuel cell hybrid line-haul locomotive solutions will be able to do”, he says. In its official statement, OptiFuel did not disclose whether the project would involve upgrading existing locomotives or building new rolling stock. UPDATED 08/02/2024: According to OptiFuel Systems reply at the ROLLINGSTOCK page in LinkedIn, fleet owners will be able choose to repower old locomotives or purchase new.

The design of the biomethane mainline locomotive (enlarge). Source: OptiFuel

The design of the biomethane mainline locomotive (enlarge). Source: OptiFuel

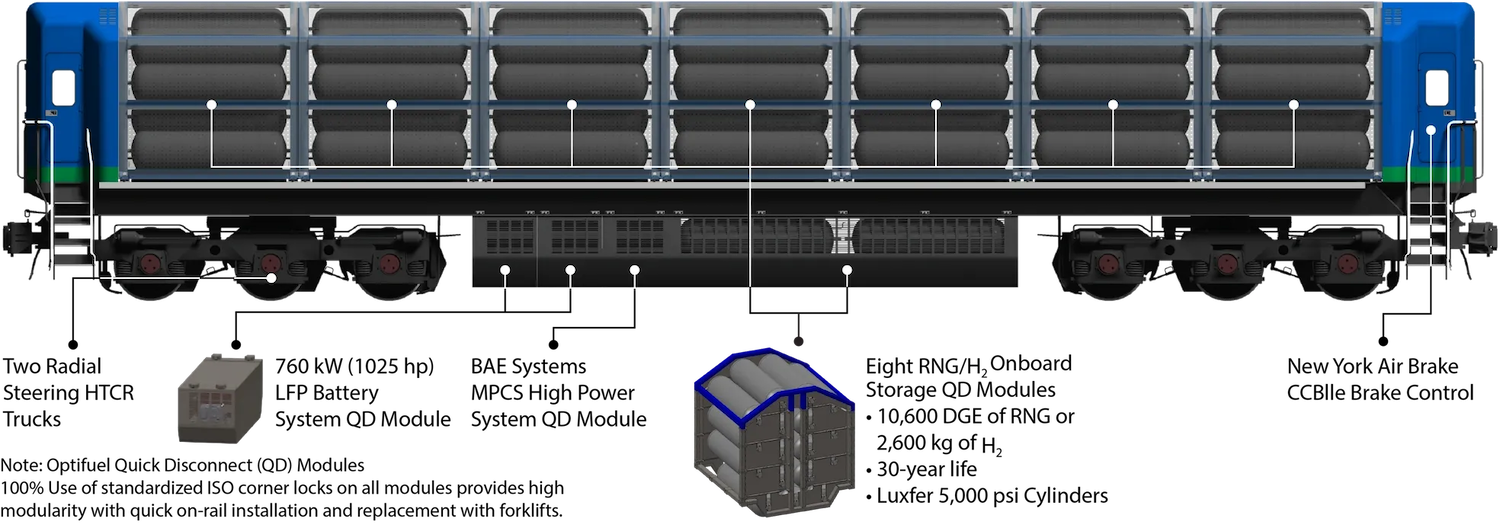

With an output of 3,750 kW in continuous mode, an LFP battery will boost this to 4,100 kW for short periods. The tender would add 1,500 kW in continuous mode and 1,850 kW in peak mode using biomethane stored in 340 atm cylinders, equivalent to 28 m3 of diesel fuel.

According to OptiFuel, the use of renewable natural gas as a fuel will result in zero emissions of nitrogen oxide and solid particles and low CO2 emissions. At the same time, the locomotive is expected to be 25% more efficient than today’s mainline diesel locomotives in terms of fuel cost and driving range.

The design of the tender for the biomethane mainline locomotive (enlarge). Source: OptiFuel

The design of the tender for the biomethane mainline locomotive (enlarge). Source: OptiFuel

OptiFuel partners with energy company GTI Energy and manufacturers of various units and components, such as Cummins (diesel engines), Luxfer Gas Cylinders (high-pressure cylinders), TMV Control Systems (control and diagnostic systems), CAF (traction converters), Knorr-Bremse subsidiary New York Air Brake (air brake systems), and others.

Beginning in January 2025, the 12-month pre-production testing will be conducted at the Federal Railroad Administration’s Transportation Technology Centre in Colorado, USA. The tests will be partially funded by a grant from the US Department of Energy. In 2026, OptiFuel plans to begin a two-year full-scale testing programme with 10 pre-production locomotives and five tenders across the US rail network. At this stage, the vehicles are expected to travel 1 mln miles (1.6 mln km). Mass production is scheduled to begin in 2028, with the cost of a mainline locomotive estimated at $5.5 mln.

The development of zero-emission alternatives to diesel in the US is being stimulated by federal grants and local legislative initiatives. For example, California will ban the operation of diesel locomotives over 23 years from 2030 and require only zero-emission new rolling stock from 2035. Amendments to the federal law allowing states to set their own emission limits were passed in December 2023.

There are only a few prototypes and projects of mainline locomotives with alternative traction in the USA. Wabtec and Progress Rail are developing hybrid and battery locomotives. In 2022, the freight operator Union Pacific announced the conversion of six diesel locomotives to hybrid traction and a gradual transition to fuel made from waste vegetable oil. Last year, the passenger operator Amtrak converted 14 Siemens Charger diesel locomotives to biofuels, which is expected to reduce CO2 emissions by 60%.