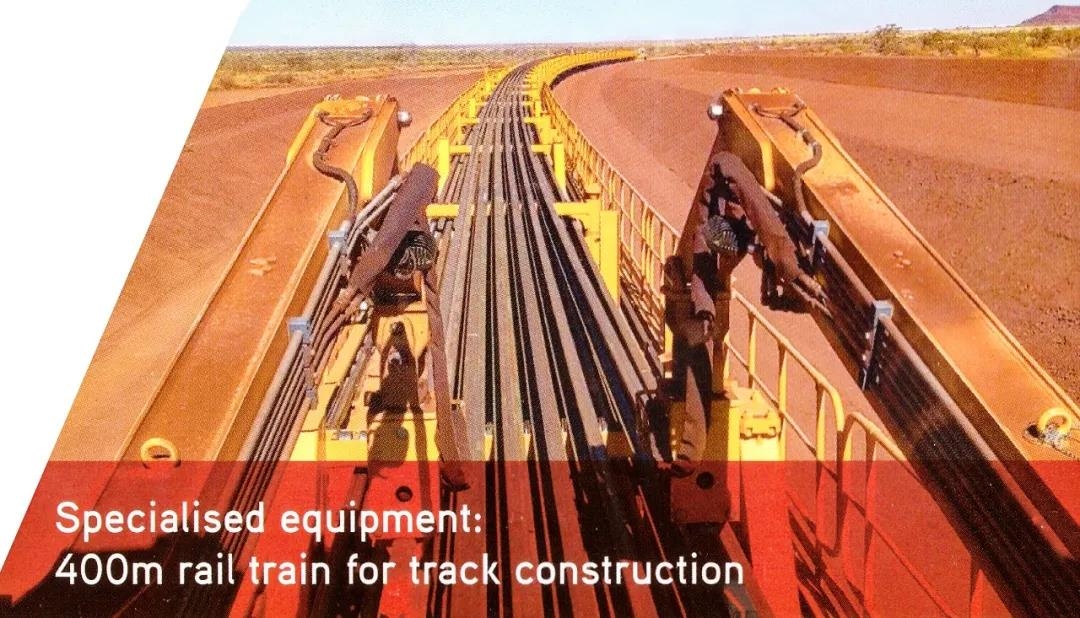

Australia: A train from a Chinese manufacturer has been approved for service operation in autumn and is being used to build a seamless track that will connect the new Koodaideri iron mine to the mining company’s rail network.

The track machine was designed by CRRC in 2019, produced in China and delivered to an Australian customer in 2020. The train consists of 23 wagons of various types and one loader crane, which is the longest element of the train, writes Railexpress. The total length of the train is 445.9 m and it can carry 40 steel rails with a length of 400 m at 68 kg/m.

It is noted that the loader crane has its own power unit, which supplies energy to the entire train. The crane also contains the сentral control system for the whole train. It is powered by solar panels and batteries installed on the train.

Source: Railexpress

Source: Railexpress

The rest of the wagons have hydraulic equipment, the coordination of which is ensured by wireless communication with the central control system. As noted by Railexpress, this approach minimizes manual labor during the loading and unloading of rails, since it requires only one operator in the center of the train, and operations for all other wagons are automated.

Rio Tinto is known for introducing the AutoHaul automated train control system in 2019: at the moment, it is the only implemented fully automated (GoA4) railway project in the world.