Russia: A new track machine is being developed by Sinara Transport Machines (STM) jointly with the Siberian Transport University (STU) in accordance with the Russian Railways (RZD) task. It is planned to release this new vehicle in 2024, but an increase in RZD’s investment program for the purchase is required.

The RShP-2.0 (RGT 2.0) project was presented at the Technoprom international forum for technological development in Novosibirsk in August. The 134 m long train will consist of three grinding sections, which will include a workshop and warehouse, a kitchen room and living quarters car, two traction sections of the overall 1,700 kW power and a converter car. RGT 2.0 will be able to receive traction both from a diesel engine and from AC/DC catenaries.

The new track machine should perform grinding 2.5 times faster than the previous RShP-48K (RGT-48) model, and the operating speed, depending on the mode, will be up to 15 km/h (for RGT-48 it is 4-6 km/h). The thickness of the rail layer removal in one pass at a speed of 15 km/h should be 0.2 mm, at a speed of 10 km/h – up to 0.3 mm. According to STM estimates, the introduction of the machine will allow RZD to increase the productivity of rail grinding operations by more than 80%. Also in 2021, Kirill Epstein, CEO of the RPM Group and director of the Track Machines Division at STM, noted during the PRO//Motion.Expo that RGT 2.0 should also help to reduce operating costs by 30%.

According to Epstein, another innovation introduced in RGT-2.0 will be a new task generation system. “Thanks to the software and connection to the unified corporate automated infrastructure management system of RZD, information about the actual state of the track in real time will be transmitted to RShP-2.0. Based on this, a task for grinding rails will be formed. After the work is completed, the data obtained using the measuring equipment will be immediately transferred to the RZD corporate management system”, he said.

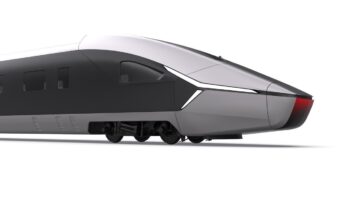

The producers and developers of the RShP-2.0 (RGT 2.0) rail grinding train (enlarge). Source: STM (translated by ROLLINGSTOCK)

The producers and developers of the RShP-2.0 (RGT 2.0) rail grinding train (enlarge). Source: STM (translated by ROLLINGSTOCK)

The development of RGT 2.0 has been carried out since 2021. Technical requirements for the advanced rolling stock were developed by a joint working group with the involvement of VNIIZhT, VNIKTI, the RZD’s Infrastructure Design Bureau and the Central Infrastructure Directorate. The rail grinding technology for RSHP-2.0 was tested at the Kuibyshev Railway in 2021. To test the technology, a prototype sample of working equipment was developed, which was installed on the smoothing bogie of RGT-48 train. The sample included 8 modernized grinding motors with a rotation speed of 5,000 rpm, installed at an “attack” angle of 0.35°. As STM reported, the trials showed an increase in total productivity compared to RGT-48 by 259%.

The release of RGT 2.0 is scheduled for 2024. However, for its implementation, it is still necessary to increase the investment program of RZD to ensure the purchase of 10 such machines by 2030. As to STM, the RZD operating fleet of RGT-48 trains is including 14 units today, and their designated service life begins to expire in 2025.