Germany: A fleet of 5 Coradia iLint 2-car hydrogen fuel cell trains by Alstom has started carrying passengers together with diesel trains on a 100 km line between Cuxhaven, Bremerhaven, Bremerwerde and Buxtehude in the Lower Saxony region. By the end of the year, the EVB operator plans to launch the remaining 9 vehicles, which will replace all diesel trains, making the line the world’s first with exceptional hydrogen traction. According to the LNVG, the transport administration of the federal state of Lower Saxony, this will save about 1.6 mln liters of diesel fuel and reduce CO2 emissions by 4,400 tons annually.

A €93 mln contract for the supply and 30-year maintenance of 14 Coradia iLint trains was signed between Alstom and LNVG in November 2017. At the same time, the hydrogen fleet will be operated by the EVB operator, which from September 2018 to February 2020 was testing two pre-series trains: during this time, their total experimental mileage exceeded 180,000 km.

Coradia iLint trials in Germany. Source: Alstom

Coradia iLint trials in Germany. Source: Alstom

The project also involves the fuel company Linde, which has built a stationary hydrogen filling station in Bremerwerde. It is equipped with 64 high pressure tanks (up to 500 bar), 6 compressors and 2 fuel pumps. In the future, it is planned to produce hydrogen “on site” using electrolysis and “green” electricity. The hydrogen refueling process is claimed to take less than 15 min. Coradia iLint will be refueled once a day, the fuel should be enough for 1,000 km of operational range. The EVB will limit the speed of trains on the line to 80-120 km/h, although they can go up to 140 km/h.

Coradia iLint train interior for EVB. Source: livemint.com

Coradia iLint train interior for EVB. Source: livemint.com

Coradia iLint is the world’s first train powered by hydrogen fuel cells. It is built on the platform of the Coradia Lint DMU, which has a passenger capacity of 300 people, including 150 seats. It also has a low-floor design. Coradia iLint was developed at Alstom’s sites in Salzgitter, Germany and Tarbes, France, as part of the German National Innovation Programme for Hydrogen and Fuel Cell Technology (NIP) with over €8 mln EUR of state funding. The train was first presented at the InnoTrans exhibition in Berlin in September 2016.

Coradia iLint train at the Innotrans exhibition in Berlin, 2016. Source: wikimedia.org

Coradia iLint train at the Innotrans exhibition in Berlin, 2016. Source: wikimedia.org

Alstom began dynamic testing of the Coradia iLint at 80 km/h at the test site of the Salzgitter plant in April 2017. A mobile filling station was installed on the site in order yo provide the train with hydrogen. The train was then sent to the VUZ test ring in Velim, Czech Republic, where the tests continued at a max speed of 140 km/h. As mentioned above, later two-year tests were carried out by the EVB in Lower Saxony, in addition, the train was also tested in Austria, Poland, Sweden and Netherlands, covering a total of 200,000 km.

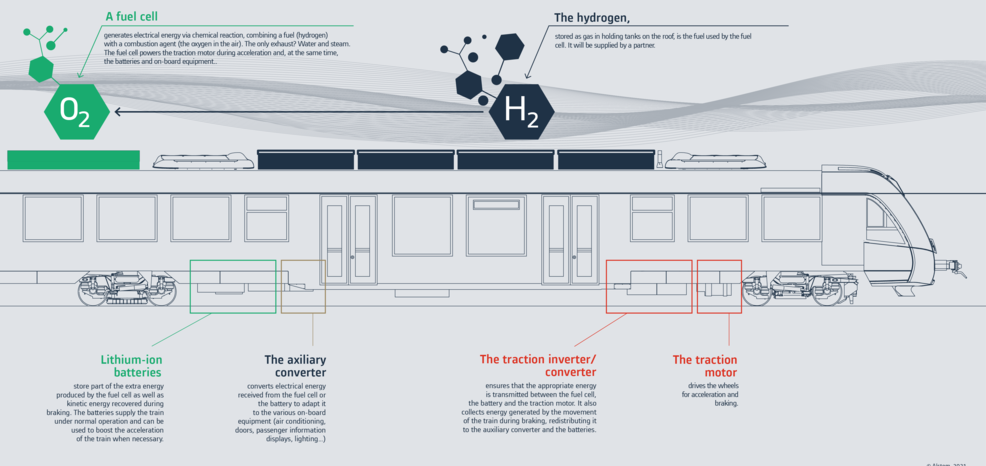

The Coradia iLint traction system consists of two 200 kW fuel cell modules, which are located on the roof of two cars. Their manufacturer is the Hydrogenics company (part of Cummins). Each module includes six sets of fuel cells, cooling systems, injection and air filtration. Also, on the roof there are tanks with liquefied hydrogen produced by Xperion. A traction electric motor, an AC/DC traction converter, an auxiliary converter and 2 lithium-ion batteries with a total capacity of 220 kW manufactured by Akasol are installed in the undercar space. In the fuel cell, hydrogen undergoes a “cold combustion” reaction with oxygen, resulting in the formation of water condensate and steam. Batteries accumulate excess energy, they also store the energy generated during regenerative braking, thereby increasing the range of the train. Excess heat is also used to heat the interior. Each car is equipped with two heating, ventilation and air conditioning units manufactured by Spheros.

The layout of the the Coradia iLint traction system elements (enlarge). Source: Alstom

The layout of the the Coradia iLint traction system elements (enlarge). Source: Alstom

A similar principle of power plant operation is used in the Mireo Plus H train presented by Siemens Moblity in May this year. The Mireo Plus H is inferior to the Coradia iLint in terms of the declared range (800 km versus 1,000 km when compared in a two-car version). The maximum speed and filling time are indicated by Siemens similarly.

Alstom’s backlog currently includes contracts for the further supply of 27 Coradia iLint trains for RMV in Germany, 14 trains for FNM in Italy, and 12 4-car trains for the French regions (with an option for 2 more trains). Alstom also recently announced the start of work on hydrogen locomotives.