Russia: The freight railcar builder is working on the certification of a bogie for a 25-t axle load. R&D is also underway in the direction of telematics and a pre-design study of a two-axle bogie for railcars with 140 km/h speed is being carried out.

Sergey Drobzhev, First Deputy CEO of RM Rail, presented a report on the prospects for the development of the company’s product line during the Rolling Stock of the XXI Century conference in July.

Key points from the presentation:

1️⃣ Certification trials of the 18-9891 bogie for a 25-t axle load is scheduled to be finished in the 4th quarter of 2022. Its design speed will be 120 km/h. The overhaul standard from construction to the first scheduled repair is declared at the level of 800,000 km or 8 years. On this bogie, the start of the next railcars serial production is planned in 2023:

-

- a tank car for nitric acid (load limit of 78.6 t, capacity of – 62 m3),

- a dump car (72 t, 40 m3),

- an autonomous refrigerated boxcar with aluminum alloy inner lining (56.5 t, 127 m3), and

- hopper wagon for mineral fertilizers with an aluminum body (79 t, 111 m3).

At a later date, the launch of serial production of 6 more railcar models of cars equipped with the 18-9891 bogies was announced.

Installation of the sensor unit on the tank car (bottom right on the cover of the axle bearing). Source: RM Rail

Installation of the sensor unit on the tank car (bottom right on the cover of the axle bearing). Source: RM Rail

2️⃣ Trials are underway in the digital technologies sphere. So, a sensor unit for railcar monitoring and diagnostics manufactured by the NPP RaTorm company was mounted on the axle bearing on the 18-9891 bogie at one of the cars. It is noted that it allows controlling:

-

- location and movement of the car,

- wheel tread,

- condition of the track,

- mileage,

- wheel diameter,

- actual speed,

- longitudinal dynamic accelerations, and

- temperature in the axle box.

The data have already been partially recorded from the installed device. As to RM Rail, the second stage of the Digital Freight Car project is currently being implemented, which includes general monitoring of railсar in operation. It is stated that tests take place at the VNIIZHT Experimental Loop in Shcherbinka, near Moscow. The later third stage involves monitoring the parameters of specific car components. The project also considers the installation of pressure sensors and the cargo condition survey.

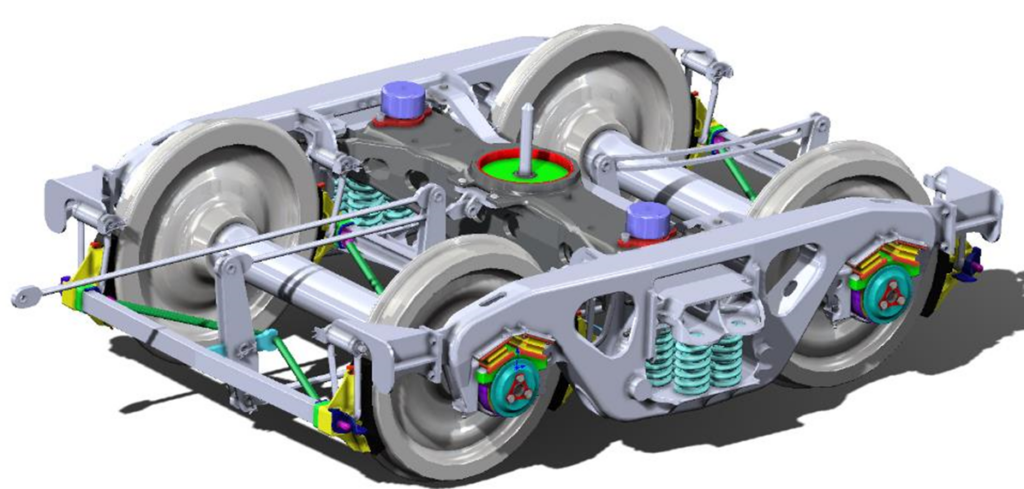

3D model of a bogie for RM Rail railcars with 140 km/h speed. Source: RM Rail

3D model of a bogie for RM Rail railcars with 140 km/h speed. Source: RM Rail

3️⃣ Pre-design work is underway on a two-axle bogie for railcars with a design speed of 140 km/h. This R&D started in November 2021. In June this year, RM Rail and Russian Railway signed an agreement of intent to develop and produce a boxcar for goods transportation on pallets and flatcars for large-capacity containers with such speed performance.

RM Rail noted that the bogie will be developed jointly with “the world’s leading companies”. Also, the development of an insulated boxcar and an articulated flatcar for 140 km/h speed is planned. The Freight One and Federal Freight operators are considered potential buyers.