Austria: The project has been implemented by the freight operator (part of the OBB Austrian national operator) since 2019 together with the A1 mobile operator and is aimed at equipping 12,000 freight cars with SmartCargo telematics devices. Initially, SmartCargo devices were to be installed on 13,700 freight cars by the end of 2020, but later these plans were adjusted.

SmartCargo consists of a GPS sensor that transmits information about the location of the railcar in certain time periods, another railcar geolocation sensor that does not depend on GPS signal reception, and an accelerometer that recognizes shock loadings in three axes and monitors the status of transported goods. The SmartCargo telematics device is powered by a rechargeable battery with a service life of 6 years. It is stated that the installed sensors transmit data to the Cumolocity cloud platform in real time.

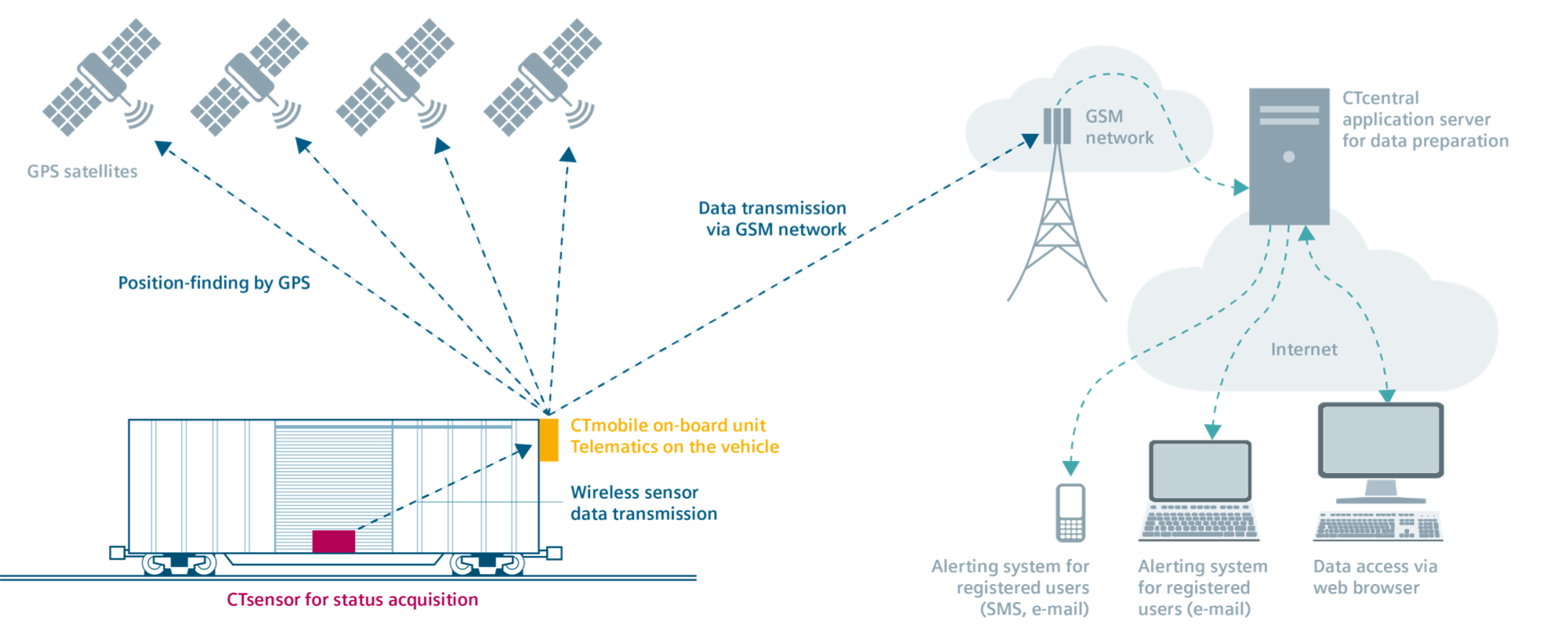

At the same time, the largest number of telematics devices among European operators are currently installed on the railcars of the DB Cargo freight operator. By 2021, 63,000 freight cars were equipped with Siemens telematics devices. The devices consist of a CTmobile unit placed under the railcar and transmitting data from sensors to the cloud storage, a GPS sensor and a set of CTsensors that monitor the physical conditions in the car, such as temperature and humidity. According to DB Cargo, clients’ access to such information allows them to better build supply chains, to control the expected time of goods arrival and the quality of transport services in general.

Scheme of Siemens telematics devices for freight cars (enlarge). Source: railwaypro.com

Scheme of Siemens telematics devices for freight cars (enlarge). Source: railwaypro.com

Also, another player who is actively implementing telematics in its fleet is worth mentioning. In March last year, the VTG leasing company entered into an agreement with the Intermodal Telematics company from Netherlands. The project involves the supply of 15,000 CLT20-Ex telematics devices powered by solar panels. It is stated that the sensors of the installed system allow to control the location of the car, the temperature of the cargo, the liquid level and the pressure in the tanks. The information transmitted by the CLT20-Ex telematics devices will be collected on the VTG cloud digital platform. Earlier, at the end of 2020, the company ordered 3,000 temperature sensors for railcars from Nexxiot (Switzerland).

In March 2021, the Swiss company Transwaggon announced plans to equip its entire fleet of freight cars with telematics. The company expects to install 7,000 Swiss-made Savvy CargoTrac ExR MI sensors by 2023. Transwaggon has been introducing such sensors since 2015: as of 2019, 7,500 out of 13,500 of its railcars were equipped with Savvy telematics. CargoTrac ExR MI sensors online determine the location of the car with an accuracy of 2 m, recognize shock loadings in three axes, which, according to Savvy, allows to quickly receive information about cargo damage.

CargoTrac ExR MI sensor. Source: SAVY

CargoTrac ExR MI sensor. Source: SAVY

At the same time, Knorr-Bremse recently announced that it intends to equip its entire product line with telematics sensors, including brake systems, doors, air conditioning systems, etc. To accomplish this task, Knorr-Bremse has acquired a stake in Nexxiot and plans to invest €60 mln in its development. Installed sensors should transmit data from components to the Nexxiot digital ecosystem, which in turn will monitor the technical condition of components in real time and predict the time until the next repair, thereby reducing the life cycle cost products. A subscription to the Nexxiot ecosystem is planned to be included in Knorr-Bremse’s future contracts with customers.